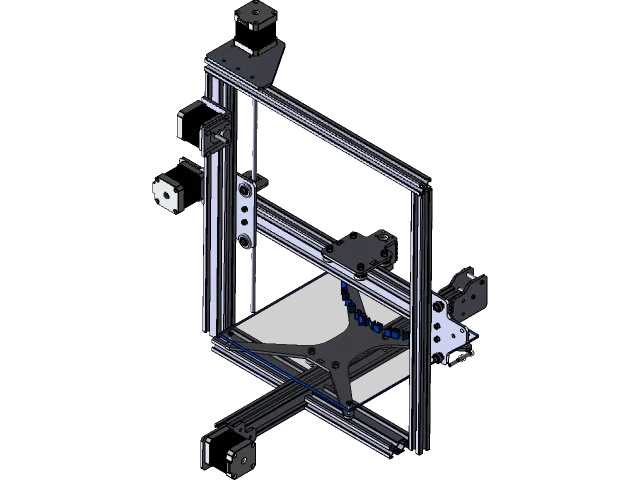

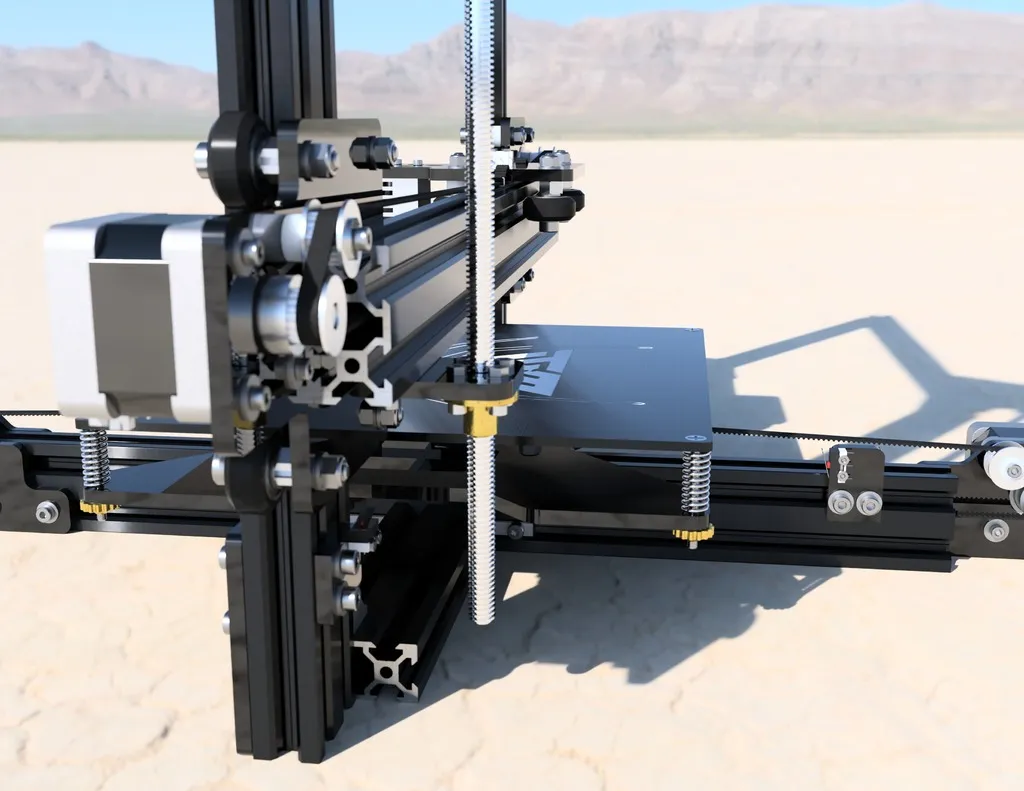

What is a Tevo Tarantula Heat Block

The Tevo Tarantula heat block is a crucial component of the 3D printer’s hot end, responsible for heating the filament to its melting point before extrusion. It is a small, usually metal, block that houses the nozzle, heating cartridge, and thermistor, working in concert to achieve and maintain the precise temperature required for printing. Proper functionality of the heat block is essential for achieving high-quality 3D prints, impacting the accuracy, strength, and overall appearance of the printed objects. Understanding the heat block’s role and components is the first step towards effective maintenance and troubleshooting, ensuring that your Tevo Tarantula operates at peak performance and produces consistent, reliable prints. Regular checks and timely upgrades can help prevent common issues, saving time and material in the long run.

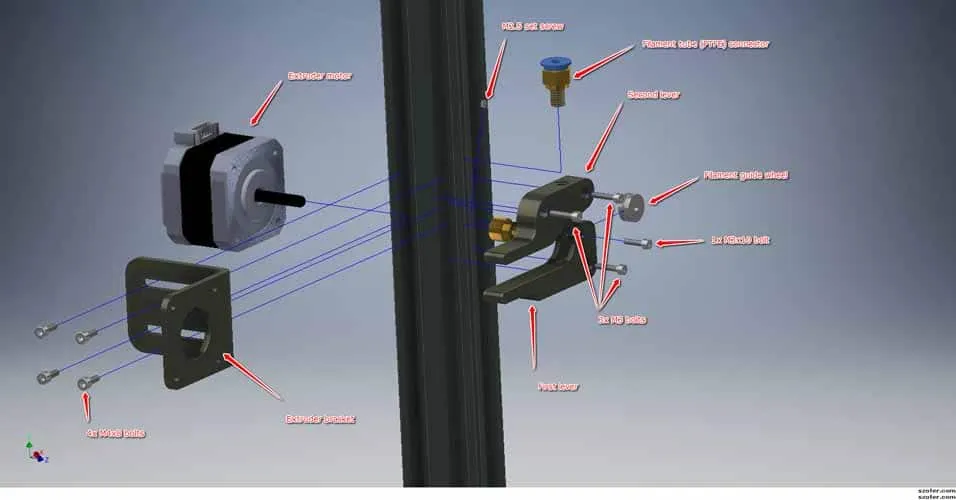

Heat Block Components

A Tevo Tarantula heat block comprises several interconnected parts, each playing a vital role in the 3D printing process. Understanding these components will greatly assist in troubleshooting and upgrading the heat block. The primary components include the nozzle, the heating cartridge, and the thermistor. Each of these elements works in harmony to control the temperature and extrusion of the filament. The quality and condition of these components directly affect print quality. Regularly inspecting and maintaining each part is a key factor in extending the life and efficiency of the heat block, ultimately contributing to more successful and satisfying 3D printing experiences.

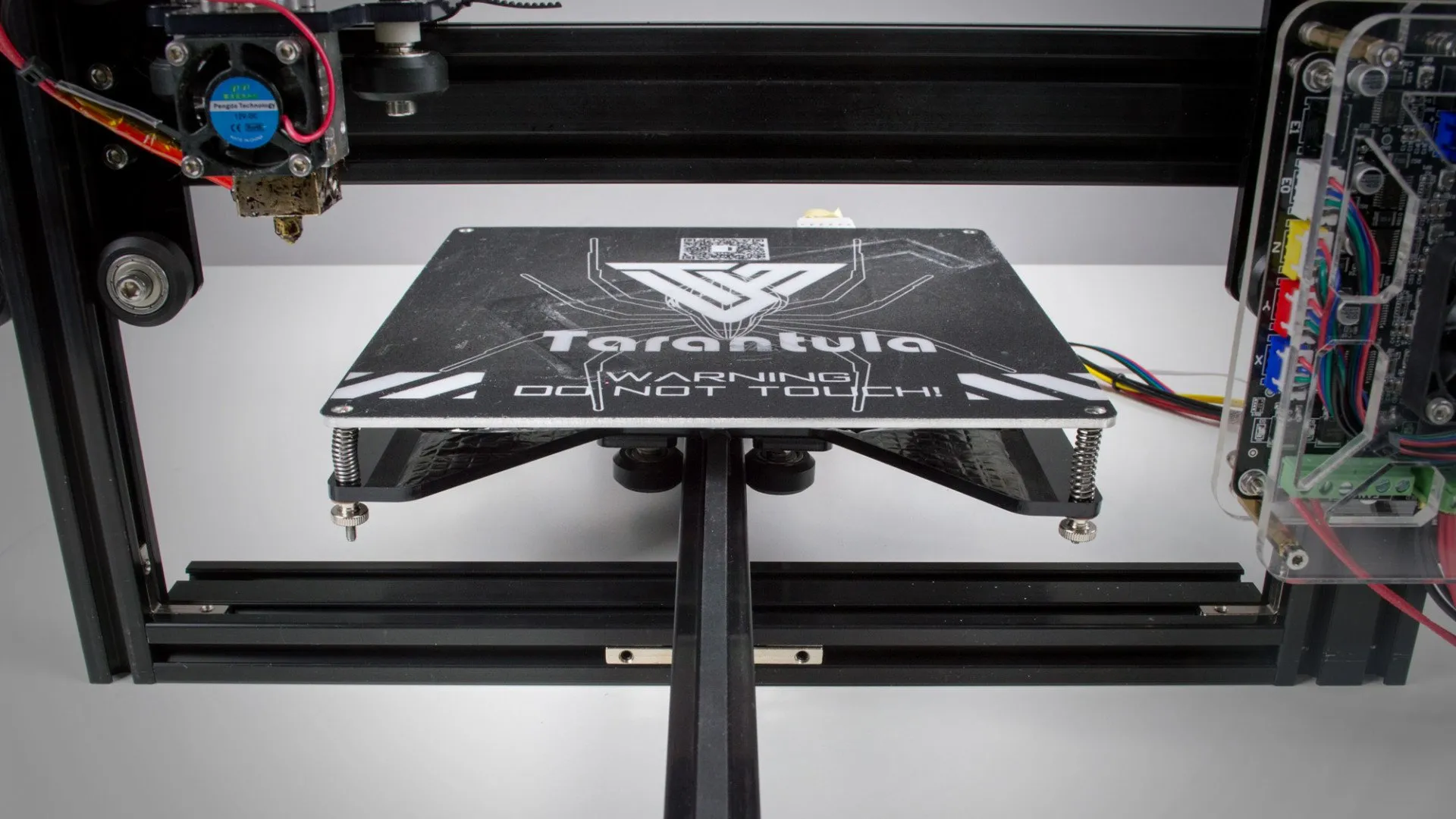

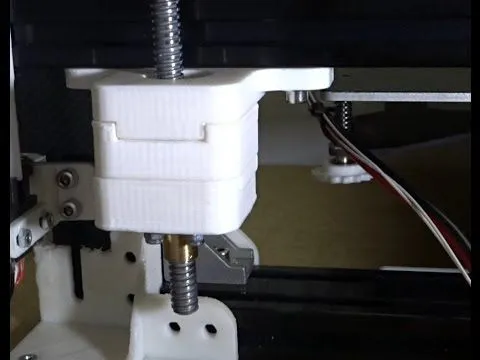

Nozzle

The nozzle is the final point of extrusion, where the molten filament is deposited onto the print bed. It is typically made of brass, stainless steel, or hardened steel, with varying orifice diameters to control the thickness of the extruded lines. The nozzle’s temperature must be precisely controlled for the filament to melt and flow smoothly. Choosing the right nozzle size depends on the desired print resolution and material being used. Nozzles can become clogged, especially if printing at incorrect temperatures or with abrasive materials. Regular cleaning and maintenance are essential to prevent these issues and ensure consistent filament flow. Careful nozzle selection and maintenance significantly impact the quality and precision of your 3D prints, affecting both fine details and overall structural integrity.

Heating Cartridge

The heating cartridge is responsible for heating the heat block and the nozzle. It is a small, cylindrical device that contains a resistive heating element. When electricity passes through this element, it generates heat. The cartridge is inserted into the heat block, which then transfers this heat to the nozzle. The heating cartridge’s wattage determines how quickly the heat block can reach the desired temperature. A properly functioning heating cartridge is critical for consistent temperature control, directly influencing print quality and the ability to print with various filament types. When the cartridge fails, it can lead to printing interruptions or inconsistent results. Regularly check the condition of the heating cartridge to make sure it’s in good working order.

Thermistor

The thermistor is a temperature sensor that monitors the temperature of the heat block. It is typically a small, bead-shaped component with two wires that connect to the 3D printer’s control board. The thermistor provides real-time temperature readings, allowing the printer to adjust the power supplied to the heating cartridge and maintain the set temperature. Accurate thermistor readings are essential for preventing overheating and ensuring optimal filament melting. A faulty thermistor can lead to inconsistent temperatures, resulting in poor print quality or even complete print failure. Regularly check the thermistor’s connection and condition to ensure accurate temperature monitoring. Replace a defective thermistor to maintain reliable and high-quality 3D prints.

Why Heat Block Matters for 3D Printing

The heat block is at the heart of your 3D printer’s ability to create accurate and high-quality prints. It directly influences several critical aspects of the 3D printing process, from print quality and consistency to the prevention of common issues such as clogs and extrusion problems. A well-maintained and properly functioning heat block will lead to better print results and a more enjoyable 3D printing experience. Focusing on the heat block will ensure the filament melts evenly, the print adheres correctly to the print bed, and your prints maintain their structural integrity. This focus is vital to prevent print failure due to temperature or extrusion irregularities. Addressing and solving heat block issues is a key component of 3D printing success.

Print Quality and Consistency

The heat block significantly impacts print quality and consistency. Precise temperature control is crucial for achieving smooth layers, fine details, and accurate dimensions. Inadequate or unstable temperatures lead to inconsistent filament melting, resulting in under-extrusion or over-extrusion. Maintaining consistent temperatures with a good heat block helps prevent warping and improves layer adhesion. The heat block’s ability to efficiently heat and maintain the correct temperature influences print quality and consistency. Regularly calibrate and monitor your heat block to make sure you’re getting the best possible print quality. Adjusting the temperature settings will prevent imperfections and make your 3D prints look great.

Preventing Clogs and Extrusion Issues

A well-maintained heat block helps prevent common issues such as clogs and extrusion problems. When the heat block doesn’t reach or maintain the correct temperature, the filament may not melt properly, leading to clogs. Conversely, if the temperature is too high, the filament may melt too quickly and ooze out, causing messy prints. Furthermore, heat creep, where heat travels up the heat break and softens the filament prematurely, can cause clogs. Proper temperature control, nozzle cleaning, and regular maintenance of the heat block reduce the likelihood of these problems. Preventing clogs and extrusion issues ensures smooth, uninterrupted printing and high-quality final products.

Common Tevo Tarantula Heat Block Problems

Even with proper maintenance, the Tevo Tarantula heat block can encounter various issues that can disrupt the printing process. Knowing the common problems can help you quickly diagnose and resolve them. These include heat creep, leaking filament, and clogged nozzles. Each issue requires a specific approach to troubleshooting. Recognizing and addressing these issues promptly can minimize downtime and maintain print quality. When troubleshooting your heat block, it’s important to first assess the problem’s symptoms and then apply the appropriate corrective measures. This knowledge is essential for any Tevo Tarantula user.

Heat Creep

Heat creep occurs when heat travels up the heat break, causing the filament to soften prematurely. This can lead to clogs, under-extrusion, and print failures. Heat creep is often caused by inadequate cooling or printing at too high a temperature. This can cause the filament to soften too early in the heat break, leading to a jam. Improving the cooling system, ensuring proper fan operation, and adjusting the printing temperature can often resolve heat creep issues. Regular maintenance, including cleaning and inspecting the heat break, can also prevent heat creep and ensure that the filament melts only at the nozzle.

Leaking Filament

Leaking filament is a common issue that occurs when the heat block components are not properly sealed, or the nozzle isn’t tightened correctly. Molten filament can escape from the heat block, creating a mess and affecting print quality. This problem is particularly noticeable during the initial heating and pre-print phase. Tightening the nozzle and other components, and making sure that the heat block is properly assembled, can resolve this issue. Additionally, checking for any gaps between components and ensuring that all parts are clean before assembly will help prevent leaks and maintain consistent filament flow. Carefully tightening the nozzle and components ensures a tight seal and prevents filament leakage, thus improving print reliability.

Clogged Nozzle

A clogged nozzle is a frequent problem in 3D printing. It obstructs filament flow and causes printing interruptions. Clogs can be caused by various factors, including printing at incorrect temperatures, using low-quality filament, or the presence of debris. To resolve a clogged nozzle, try using a needle to clear the obstruction, or heat the block and manually push filament through the nozzle. Regular maintenance, including cleaning the nozzle and using a filament filter, helps prevent clogs. Using a nozzle cleaning tool can greatly assist in removing debris and other obstructions, making your printer more efficient. Replacing your nozzle may be required, if cleaning is not successful.

How to Troubleshoot Your Heat Block

When encountering heat block issues, systematic troubleshooting is essential to identify and resolve the problem efficiently. Begin by inspecting the nozzle, heating cartridge, and thermistor. If a clog is suspected, try a cold pull to remove any debris. Examining the wiring and connections of each component can help identify electrical issues. Testing the thermistor with a multimeter will confirm whether it is functioning correctly. Documenting the symptoms, the steps taken to resolve them, and the outcomes can help you learn from your experiences and improve your future troubleshooting skills. Accurate diagnosis and quick, effective solutions will minimize downtime and enhance your 3D printing experience.

Inspecting and Cleaning the Nozzle

Regularly inspect the nozzle for clogs or damage. Carefully heat the heat block to the filament’s printing temperature and use a nozzle cleaning tool to remove any debris. You can also use a fine needle to clear blockages. If the nozzle is worn or damaged, it should be replaced. By performing these routine checks, you can prevent extrusion problems and ensure optimal print quality. Cleaning and maintaining the nozzle is a small but essential part of 3D printing success, preventing issues such as blobs and inconsistencies in your prints. It will help extend the life of your printer and make certain that you obtain the best results.

Checking the Heating Cartridge

The heating cartridge should be inspected for any signs of damage or wear. Check the wiring and connections to ensure they are secure. Use a multimeter to test the cartridge’s resistance, comparing the reading to the manufacturer’s specifications. If the cartridge is faulty, replace it with a compatible one. Proper maintenance of the heating cartridge will help guarantee consistent temperatures and prevent printing failures. Make sure the heating cartridge sits flush in the heat block to ensure efficient heating. A properly functioning cartridge is a fundamental component of a working heat block, and contributes to overall print quality and success.

Verifying Thermistor Functionality

The thermistor’s functionality can be tested by checking its resistance at room temperature and heating it to determine if the resistance decreases. If the thermistor’s resistance is outside of the expected range, it should be replaced. Check the wires and connections for any damage or loose connections. Verify that the thermistor is securely mounted in the heat block. Accurate temperature readings are crucial for successful printing. A malfunctioning thermistor can result in print failures and printing errors. Regular verification of its functionality ensures that your printer can maintain the right temperatures for different filaments, contributing to your 3D printing success.

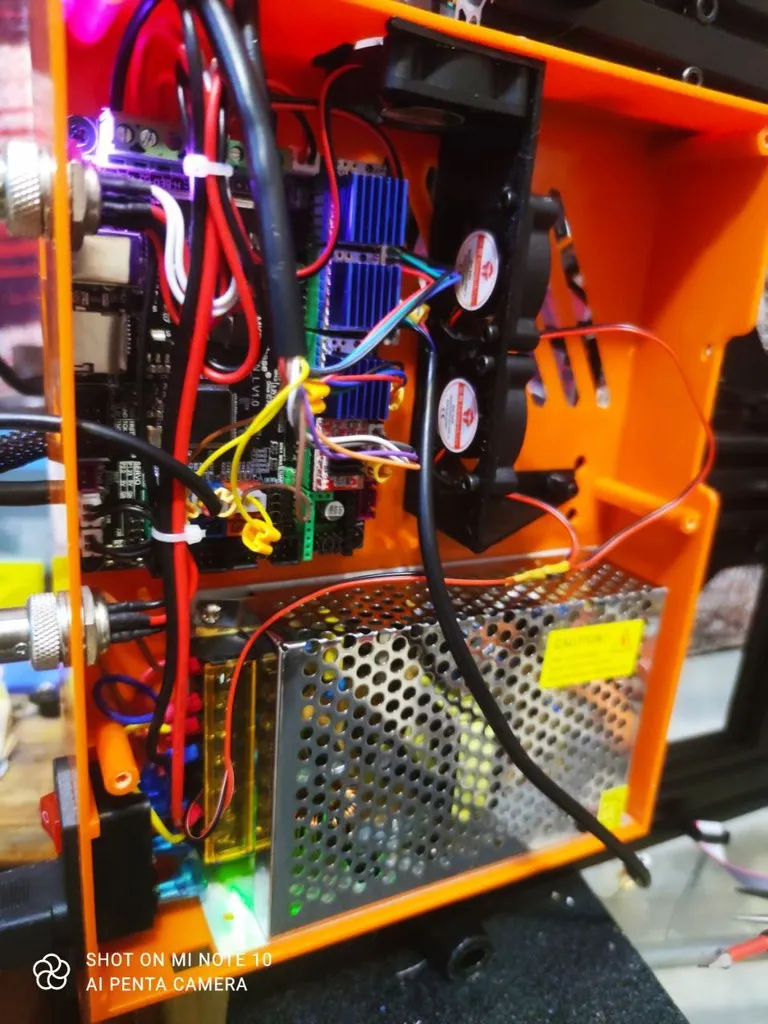

Upgrading Your Tevo Tarantula Heat Block

Upgrading your Tevo Tarantula heat block can significantly improve its performance and print quality. There are several advantages, from enhancing temperature control to increasing the range of compatible filaments. The available upgrades range from simple nozzle replacements to more complex full-heat block replacements. Considering what you hope to achieve with your printer is the first step when deciding which upgrades are best for you. These upgrades can enhance print accuracy and the types of materials you can print. This allows you to experiment with different settings and materials.

Benefits of Upgrading

Upgrading your heat block provides multiple benefits. Improved temperature stability leads to consistent print quality and greater print accuracy. Enhanced heat distribution allows for faster printing speeds and better layer adhesion. Compatibility with a wider range of filaments, from standard PLA to more advanced materials, expands your printing options. Improved overall print quality, including better surface finish, and the potential to solve existing issues like heat creep, makes your prints better. Upgrading the heat block is a good investment for improving your 3D printing experience, allowing you to take advantage of new materials and better print quality.

Types of Upgrades

Several types of upgrades are available for the Tevo Tarantula. Replacing the nozzle with a hardened steel or nozzle made of other materials improves performance and durability. Upgrading to a full all-metal heat block offers more efficient heating and the ability to print with higher-temperature materials. Installing a silicone sock improves temperature stability and reduces heat loss. Each upgrade has its specific benefits and may involve varying degrees of difficulty during installation. When choosing an upgrade, consider your printing needs, desired performance enhancements, and the compatibility with your specific printer model.

Installation Guide

Installing a new heat block requires following safety precautions and a series of carefully executed steps. Disconnect the printer from the power supply. Remove the existing heat block and its components, noting how everything fits together. Install the new components, ensuring that they are correctly aligned and secured. Make sure that all connections are tight, and double-check that everything is correctly assembled. Refer to the manufacturer’s instructions for specific installation steps, which are usually included with the product. After installation, it is necessary to test and calibrate the printer to ensure that everything works correctly. A proper and successful installation guarantees that you will get the desired performance from your new heat block.

Best Practices for Heat Block Maintenance

Regular maintenance is vital to keep your Tevo Tarantula heat block in top condition and ensure consistent performance. Simple practices such as regular cleaning and proper component tightening can prevent numerous problems. By following these maintenance steps, you can extend the life of your heat block and improve the quality of your prints. Dedicate time for maintenance, as regular checks will improve the quality of your prints. A maintenance routine will prevent malfunctions and make sure that your 3D printer operates efficiently.

Regular Cleaning Schedule

Establish a regular cleaning schedule to remove accumulated debris and filament residue. Clean the nozzle after each print or after every few prints, particularly when using different filaments. Use a nozzle cleaning tool or a fine needle to remove any clogs. Regularly clean the heat block’s exterior to prevent filament buildup. Cleaning the heat block after each print can help to avoid clogs. Regular cleaning can greatly improve the reliability of your printer. By implementing these practices into your routine, you can extend the life of your equipment and get better results.

Proper Tightening of Components

Ensuring the nozzle, heating cartridge, and thermistor are properly tightened is vital. Check these components for tightness before each print. Do not overtighten the nozzle as this can cause damage; consult the manufacturer’s recommendations. Correctly tightened components ensure that there are no filament leaks or temperature fluctuations. Inspecting and tightening the heat block components regularly is key to preventing printing issues and improving overall print quality. Proper tightening ensures a tight seal and stable temperature, which enhances the printing experience.

Heat Block Safety Tips

Always disconnect the power supply before performing any maintenance or upgrades. Allow the heat block to cool before handling it to prevent burns. Use heat-resistant gloves and tools when working on a heated component. Be cautious when using sharp tools and avoid touching the heating components directly. Work in a well-ventilated area to minimize exposure to fumes. Following these safety tips will help protect yourself and your printer. Remember, your safety is always paramount when working with 3D printers. By following these steps, you can ensure your safety and have a secure printing experience.