The Tevo Tarantula, a popular and affordable 3D printer, is a favorite among hobbyists and enthusiasts. While the Tarantula offers a great starting point for 3D printing, upgrading the Z-axis bracket can significantly improve print quality and overall performance. This guide provides the top 5 tips for optimizing your Tevo Tarantula’s Z-axis bracket, helping you achieve smoother and more accurate 3D prints. Whether you’re a beginner or an experienced user, these tips will enhance your printing experience and reduce common issues. By focusing on stability, alignment, and vibration reduction, you can transform your Tevo Tarantula into a reliable and high-performing 3D printing machine.

Understanding the Tevo Tarantula Z-Axis Bracket

The Z-axis bracket is a critical component of the Tevo Tarantula, responsible for supporting and guiding the Z-axis rods, which control the vertical movement of the print head. A well-designed and properly installed Z-axis bracket ensures the stability of the print bed and nozzle during printing. This stability directly affects layer adhesion, dimensional accuracy, and the overall quality of your prints. The original bracket on the Tevo Tarantula can sometimes be prone to flex or misalignment, which can lead to several printing issues. Upgrading or modifying this bracket is a common and effective way to improve the printer’s performance. This section provides an overview of the Z-axis bracket’s function and its impact on print quality, making it easier to understand why these upgrades are important.

Importance of a Stable Z-Axis

A stable Z-axis is paramount for achieving high-quality 3D prints. When the Z-axis is unstable, the print bed and nozzle may wobble or shift during printing, resulting in inconsistent layer heights, poor layer adhesion, and visible imperfections. A wobbly Z-axis can cause issues like ringing, ghosting, and dimensional inaccuracies, which significantly affect the final product’s appearance and functionality. Ensuring the Z-axis bracket is secure and properly aligned minimizes these problems, providing a solid foundation for your prints. A stable Z-axis also contributes to quieter operation and reduces the chances of mechanical failures. By addressing Z-axis instability, you pave the way for improved print accuracy, smoother surfaces, and overall better printing results.

Common Z-Axis Bracket Issues

Several common issues can affect the performance of the Tevo Tarantula’s Z-axis bracket. These issues can range from minor inconveniences to major problems that impact print quality. Flexing of the bracket itself can occur, especially with the original design. This flex can result in slight shifts in the Z-axis position during printing. Misalignment is another significant issue, caused by improper installation or wear over time. Even a slight misalignment can cause significant printing errors. Loose screws and bolts are also a concern, as they can allow the bracket to shift and cause instability. Vibration can also be a major problem, particularly at higher print speeds or with certain materials, and can lead to noticeable print artifacts. Finally, wear and tear on the bracket or associated components like the Z-axis rods can also contribute to issues, leading to a decline in print quality over time.

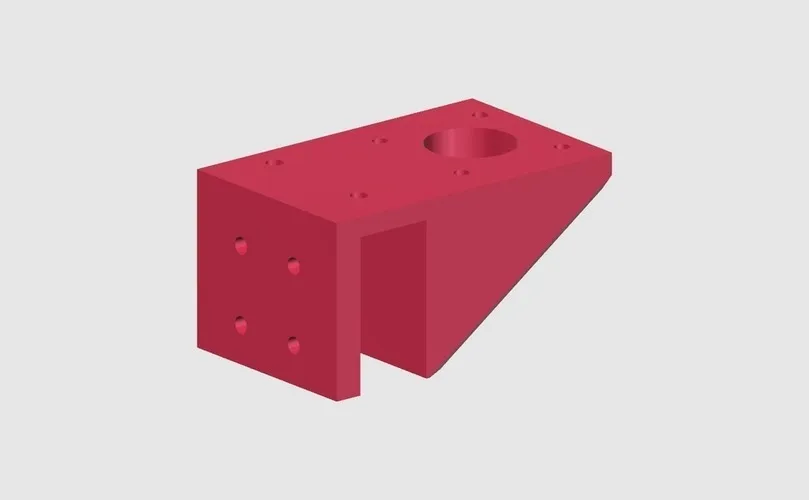

Tip 1 Choosing the Right Z-Axis Bracket

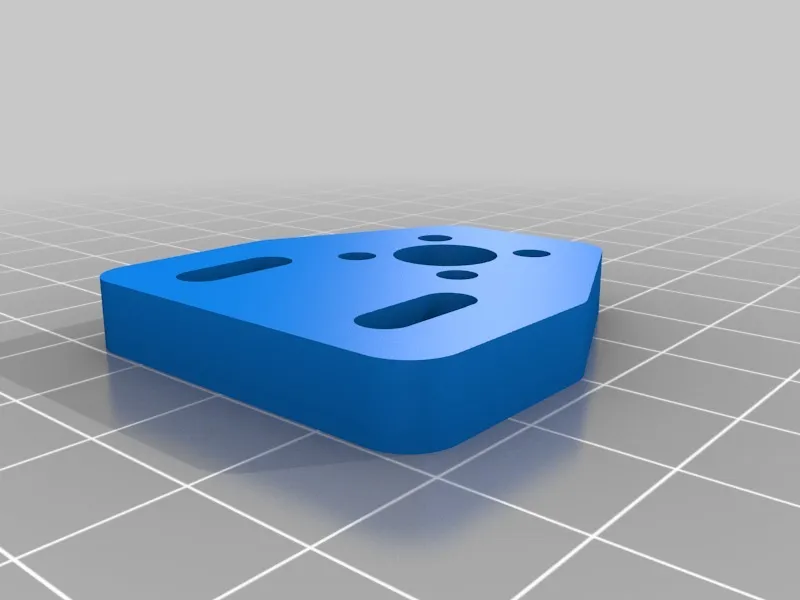

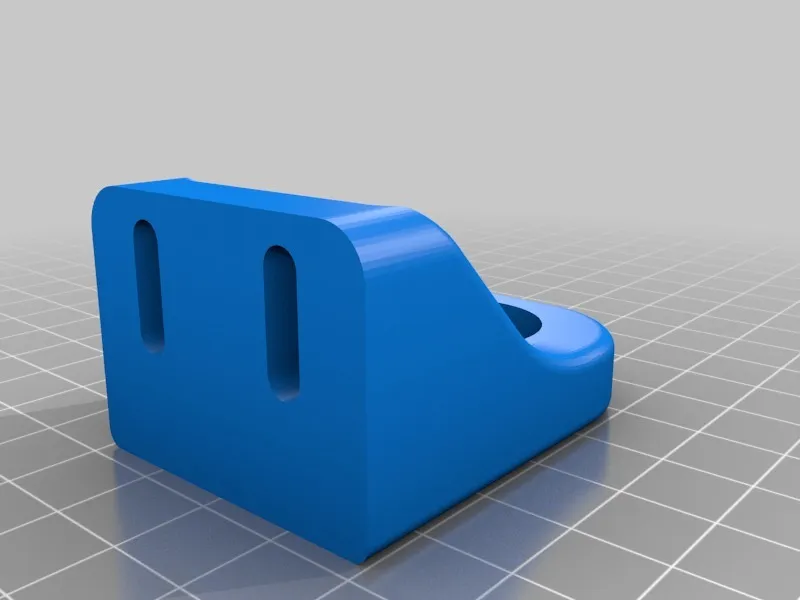

Selecting the right Z-axis bracket is the first crucial step in improving your Tevo Tarantula’s performance. There are several options available, including upgrades made from more robust materials like aluminum or reinforced plastic. When choosing a bracket, consider the material, design, and compatibility with your printer. Upgraded brackets often provide improved stability and reduce flex compared to the original. Look for brackets that are specifically designed for the Tevo Tarantula to ensure a proper fit and easy installation. Also, read reviews and compare features to make an informed decision, prioritizing brackets that offer enhanced rigidity and a secure mounting system. This will set the stage for better printing results.

Material Considerations

The material of your Z-axis bracket significantly impacts its performance. Aluminum brackets are popular due to their rigidity and durability, providing excellent stability and reducing flex. Reinforced plastic brackets are another option, often offering a good balance of strength and cost-effectiveness. Consider the environment in which your printer operates, as some materials may be more resistant to wear and tear or temperature fluctuations. Avoid brackets made from flimsy materials, as they may not provide the necessary support and stability. The choice of material should be based on your specific needs, budget, and the demands of your printing projects. Investing in a high-quality material can prevent future issues and improve print quality.

Design Factors

Several design factors contribute to a Z-axis bracket’s effectiveness. Look for brackets with a robust design that minimizes flex and ensures a secure fit. The mounting mechanism should be sturdy and easy to install, with clear instructions provided. Consider the bracket’s compatibility with your printer’s existing components, such as the Z-axis rods and motor mounts. A well-designed bracket will provide smooth and precise Z-axis movement, contributing to better print quality. Some brackets include features like adjustable endstops and integrated mounting points for accessories. Prioritize designs that prioritize stability, ease of use, and compatibility with your printer’s setup. Consider the overall build quality and the manufacturer’s reputation.

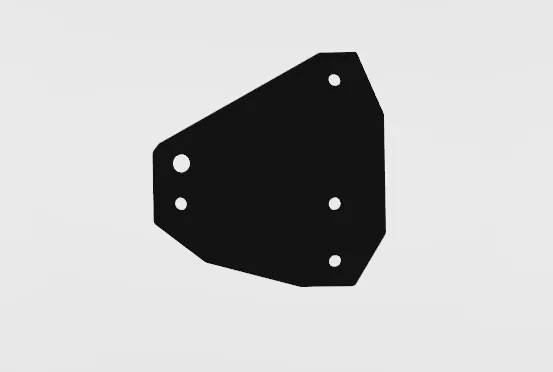

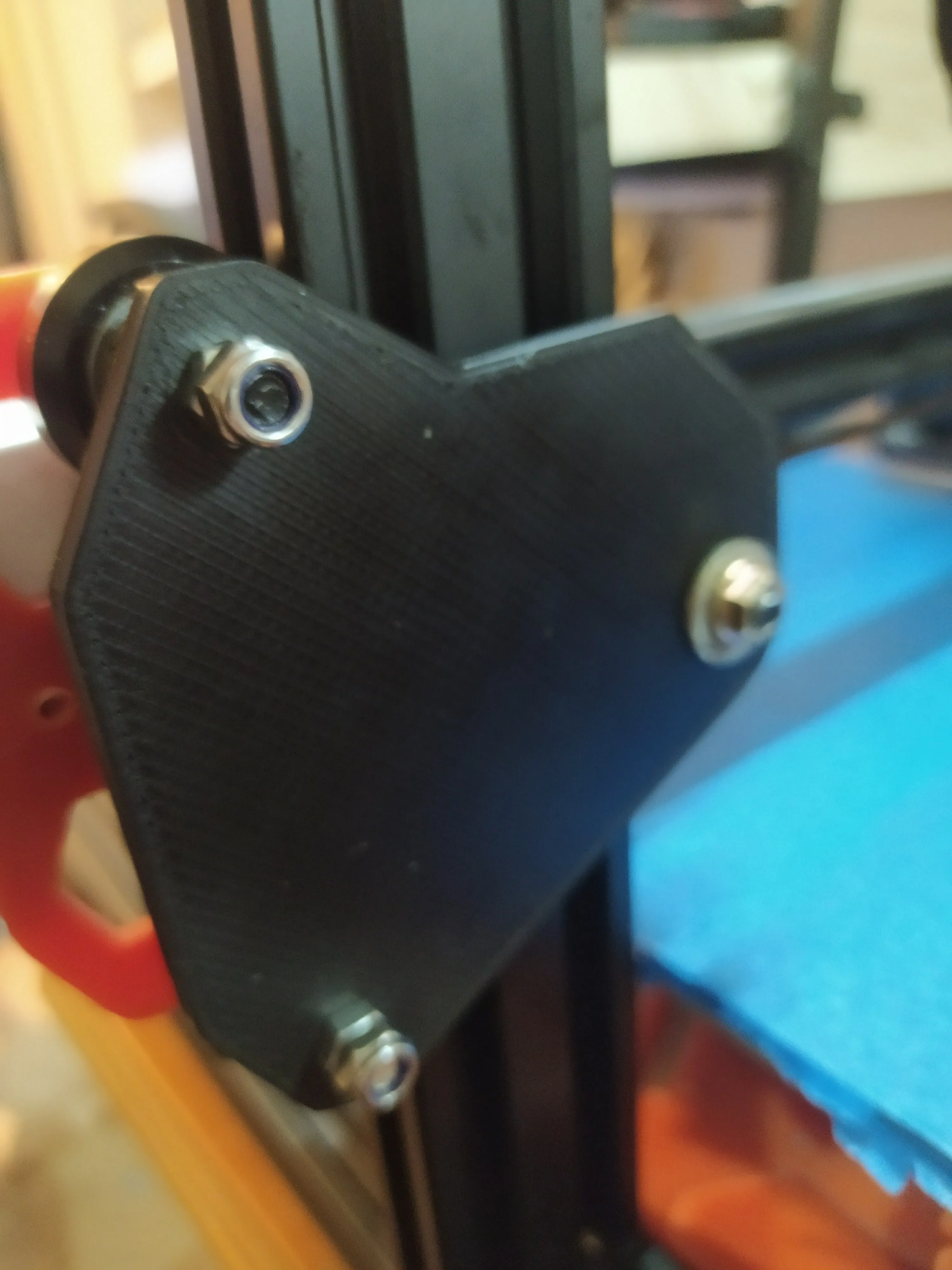

Tip 2 Proper Installation and Alignment

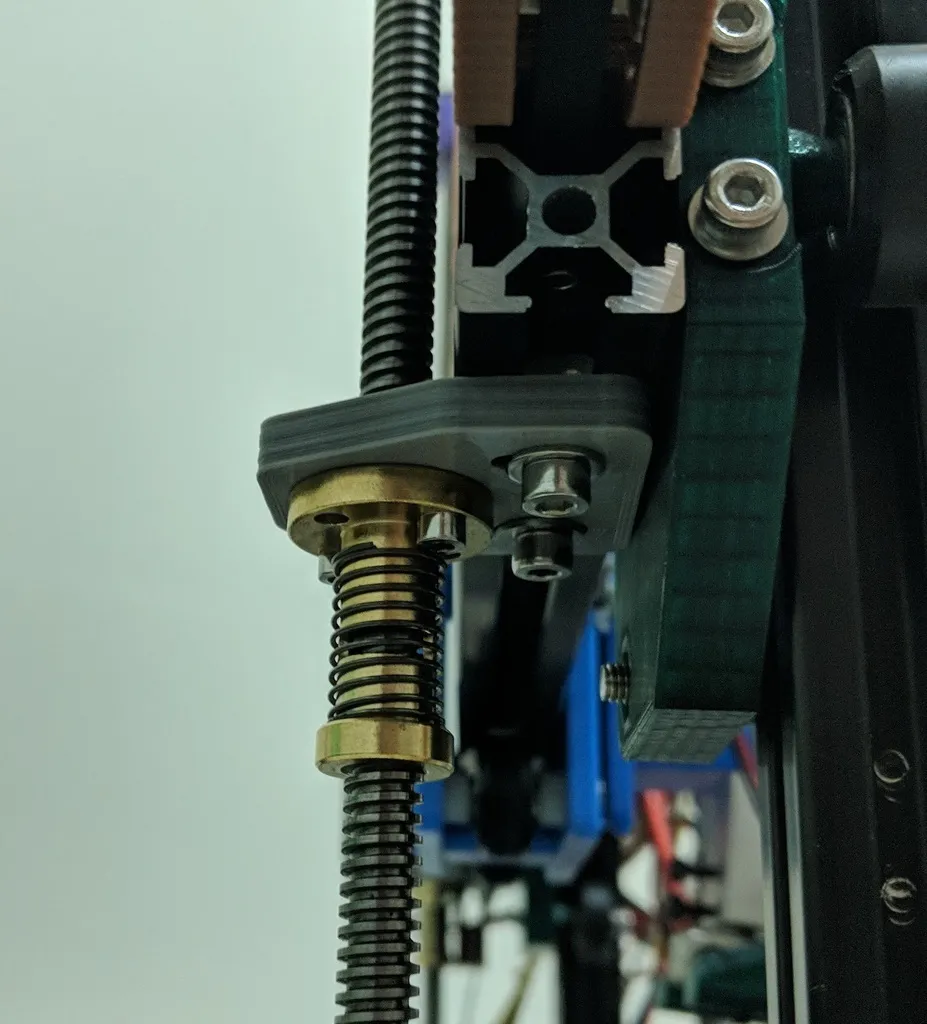

Proper installation and alignment of the Z-axis bracket are critical for achieving optimal print quality. Follow the manufacturer’s instructions carefully, ensuring all screws and bolts are securely tightened. Use the correct tools and take your time to avoid damaging the bracket or other printer components. Incorrect installation can lead to misalignment and printing issues. After installing the bracket, carefully align the Z-axis rods to ensure they are perfectly vertical and parallel. Misalignment can cause the print bed to tilt, leading to uneven first layers and poor print adhesion. Double-check all connections and ensure the Z-axis moves smoothly and without binding. Proper installation and alignment will establish a solid foundation for accurate and reliable prints.

Step-by-Step Installation Guide

The installation process varies depending on the bracket design. However, the general steps typically include: Disconnecting power from your printer and removing the existing Z-axis bracket. Identifying all necessary parts and tools. Attaching the new bracket to the printer frame using the provided screws or bolts. Carefully aligning the Z-axis rods and securing them in the bracket. Tightening all screws and bolts gradually and evenly to avoid over-tightening. Verify the stability and movement of the Z-axis. It is recommended to consult the manufacturer’s instructions and any available online resources for detailed instructions specific to your chosen bracket. By following these steps carefully, you can ensure a successful and trouble-free installation.

Ensuring Accurate Alignment

Accurate alignment is essential for optimal print quality. The Z-axis rods must be perfectly vertical and parallel to ensure the print bed moves smoothly and evenly. Use a level or a straight edge to check the vertical alignment of the rods. Ensure the distance between the rods is consistent along their entire length. If needed, adjust the bracket’s position or use shims to correct any misalignment. Proper alignment reduces the risk of layer shifting and other printing defects. Additionally, test the Z-axis movement by manually moving the print bed up and down, checking for any binding or resistance. Fine-tune the alignment until the Z-axis moves freely and smoothly.

Tip 3 Reducing Vibration

Vibration can significantly impact print quality, leading to ringing, ghosting, and other artifacts. Reducing vibration in the Z-axis system can greatly improve your prints. Begin by identifying the sources of vibration and taking steps to mitigate them. Using higher-quality belts and pulleys can reduce noise and vibration. Ensure the printer is placed on a stable surface and consider using vibration-damping feet. Properly tension the belts on your 3D printer to ensure they don’t vibrate excessively. By taking these steps, you can minimize the effects of vibration and achieve cleaner, more accurate prints. Proper reduction of vibration is very important to achieve a perfect first layer.

Identifying Vibration Sources

Several components can contribute to vibration in your 3D printer. The Z-axis motor, belts, and pulleys are common sources. The print bed itself, especially if it is heavy or not properly supported, can also vibrate during printing. External factors, such as the surface on which the printer is placed, can also contribute to vibration. The print speed and acceleration settings can also amplify vibrations. Identify the source of the vibration by observing your printer during operation. Listen for unusual noises and feel for any movement or shaking. Once you identify the source, you can take appropriate measures to reduce vibration, such as tightening loose components or adjusting print settings.

Damping Techniques

Several damping techniques can minimize vibration. Using vibration-damping feet under the printer can isolate it from the surface and reduce the transmission of vibrations. Adding mass to the printer frame can help to absorb vibrations. Tightening belts and pulleys can reduce vibrations caused by movement. Consider replacing stock components with higher-quality alternatives designed to reduce vibration. Adjusting print settings, such as reducing print speed and acceleration, can also minimize vibration. By combining these techniques, you can create a more stable and vibration-free printing environment, resulting in higher-quality prints. Experimenting with different approaches can help you find the most effective solution for your specific printer setup.

Tip 4 Maintenance and Inspection

Regular maintenance and inspection of your Z-axis bracket are crucial for maintaining optimal performance and extending its lifespan. Periodically check for loose screws, bolts, and other components and tighten them as needed. Inspect the bracket for any signs of wear, damage, or misalignment. Lubricate moving parts, such as the Z-axis rods and bearings, with appropriate lubricant to ensure smooth operation. Keep the printer clean and free from dust and debris, as this can affect its performance. Regular maintenance will prevent issues and ensure your printer operates at its best. By proactively addressing any problems, you can maintain consistent print quality and reduce the risk of unexpected failures. Proper maintenance ensures that your prints always come out great.

Regular Checks and Adjustments

Establish a maintenance schedule to regularly check and adjust your Z-axis bracket. Inspect the bracket for any signs of looseness or misalignment before each print or at least every few prints. Check the screws and bolts and tighten them as needed. Verify the alignment of the Z-axis rods, ensuring they are perfectly vertical. Monitor the movement of the Z-axis and ensure it is smooth and free from binding. Perform adjustments as needed to maintain proper alignment and stability. These regular checks and adjustments will help to catch any problems early and prevent them from developing into larger issues. This proactive approach will save you time and frustration in the long run.

Identifying Wear and Tear

Wear and tear can occur on the Z-axis bracket and its associated components over time. Regularly inspect the bracket for any signs of damage, such as cracks, bends, or deformation. Examine the Z-axis rods for any scratches, wear, or damage. Check the bearings for wear or roughness, and replace them if necessary. Monitor the performance of the Z-axis and listen for any unusual noises. Replace worn or damaged components promptly to maintain print quality and prevent further damage. By identifying and addressing wear and tear, you can ensure the long-term reliability of your 3D printer and maintain the quality of your prints. Addressing these issues prevent major breakdowns during longer print runs.

Tip 5 Software and Firmware Adjustments

Software and firmware settings can also impact your printer’s performance. Calibrating the Z-axis and making adjustments to the firmware can optimize print quality and minimize common issues. Proper calibration ensures accurate layer heights and dimensional accuracy. Firmware settings, such as acceleration and jerk control, can be adjusted to minimize vibration and improve print quality. Regularly update your printer’s firmware to the latest version to benefit from bug fixes and performance improvements. By taking advantage of software and firmware adjustments, you can fine-tune your printer’s performance and get the best possible prints. These settings are essential to the overall quality.

Calibration Techniques

Calibration is a critical step in ensuring accurate prints. Calibrate the Z-offset to ensure the nozzle is at the correct height relative to the print bed. Use the bed leveling process to ensure the print bed is level across its surface. Run a first-layer test print and make adjustments to the Z-offset and bed leveling as needed until you achieve the correct first-layer adhesion and spacing. The Z-steps/mm setting in your printer’s firmware determines the distance the Z-axis moves for each step of the motor. Calibrate this setting to ensure the Z-axis moves the correct distance, which impacts layer heights and dimensional accuracy. Properly calibrating the Z-axis will eliminate many printing problems.

Firmware Settings

Firmware settings can significantly affect print quality. Adjust acceleration and jerk settings to reduce vibration and improve print quality. Lowering these settings can reduce ringing and ghosting artifacts. Adjust the Z-axis steps/mm setting in the firmware to ensure accurate vertical movement. Firmware updates can also improve performance and resolve issues. Enable features like linear advance in the firmware to improve print quality, especially for more intricate designs. Experiment with different settings and monitor the results to fine-tune your printer’s performance. Understanding and adjusting firmware settings allows you to customize your printer’s performance to your specific needs and printing style.

Conclusion Improving Z-Axis Performance

Improving the Z-axis bracket on your Tevo Tarantula can significantly enhance print quality, reliability, and overall user experience. By following the tips outlined in this guide, you can optimize your printer for superior results. Start by choosing the right bracket made of robust materials, then install and align it correctly to prevent the most common issues. Reducing vibration through damping techniques and adjusting printer settings is a key factor in smooth printing. Remember to perform regular maintenance and make software adjustments to fine-tune your printer’s performance. Implementing these strategies will transform your Tevo Tarantula into a dependable and high-performing 3D printing machine, letting you achieve excellent results in your projects. Consistent attention to detail ensures outstanding prints.