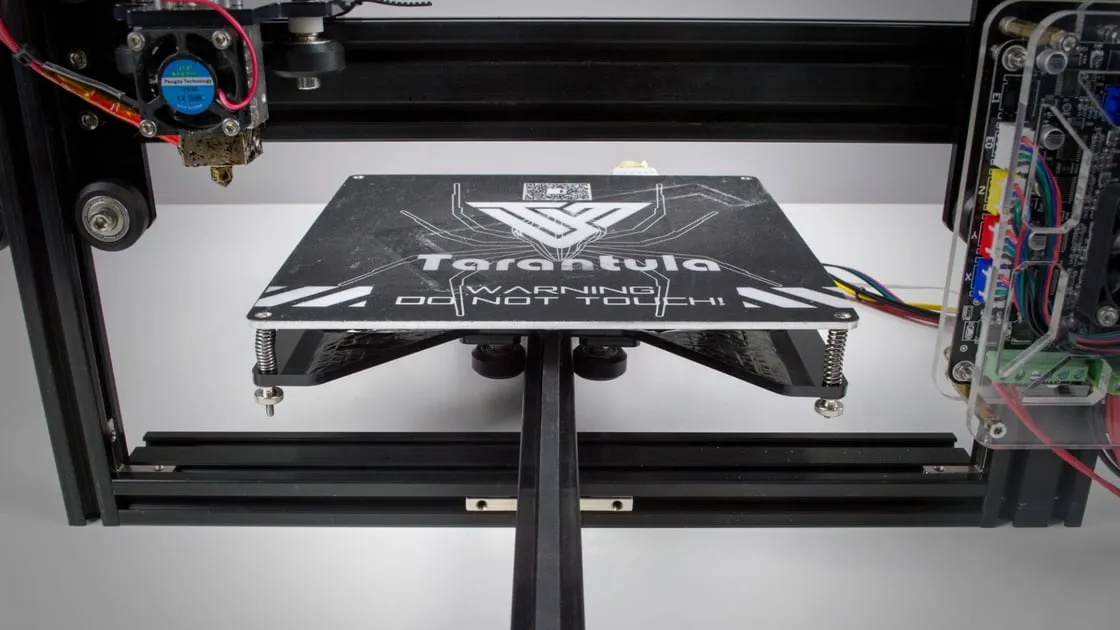

What is Z Offset & Why Is It Important for Tevo Tarantula?

The Z offset is a critical setting in 3D printing, especially for the Tevo Tarantula, as it determines the distance between your printer’s nozzle and the print bed. This seemingly small adjustment has a massive impact on the quality of your first layer, which is the foundation upon which your entire print is built. A correctly calibrated Z offset ensures that the filament adheres properly to the bed, preventing warping, poor adhesion, and other common print failures. Incorrect Z offsets can lead to a variety of problems, from the nozzle scraping across the bed to the filament not sticking at all.

Understanding the Z Offset

Think of the Z offset as the fine-tuning mechanism for the printer’s vertical position. When you start a print, the printer moves the nozzle to the correct X and Y coordinates, but the Z offset ensures the nozzle is the precise distance above the bed. The printer’s firmware uses this offset value to compensate for any discrepancies between the theoretical and actual position of the nozzle. A negative Z offset means the nozzle is closer to the bed than the printer thinks, and a positive value indicates it’s further away. Getting this value right is crucial for a good first layer, leading to a successful print.

Importance of Correct Z Offset

A properly set Z offset is paramount for successful 3D printing. When the nozzle is too close to the bed (negative Z offset), the filament may not extrude properly, and the nozzle might even scratch the bed. Conversely, if the nozzle is too far away (positive Z offset), the filament won’t stick to the bed, leading to warping and detachment. The perfect Z offset provides the optimal squish of the first layer, allowing the filament to adhere to the bed and create a strong foundation for subsequent layers. Without a correct Z offset, you’ll experience frustrating print failures and wasted filament.

Tools and Materials Needed for Z Offset Calibration

Fortunately, calibrating the Z offset on your Tevo Tarantula doesn’t require a lot of specialized tools. The process is straightforward and can be completed with items you likely already have. Accuracy and precision are key when adjusting the Z offset, so take your time and be patient during the process.

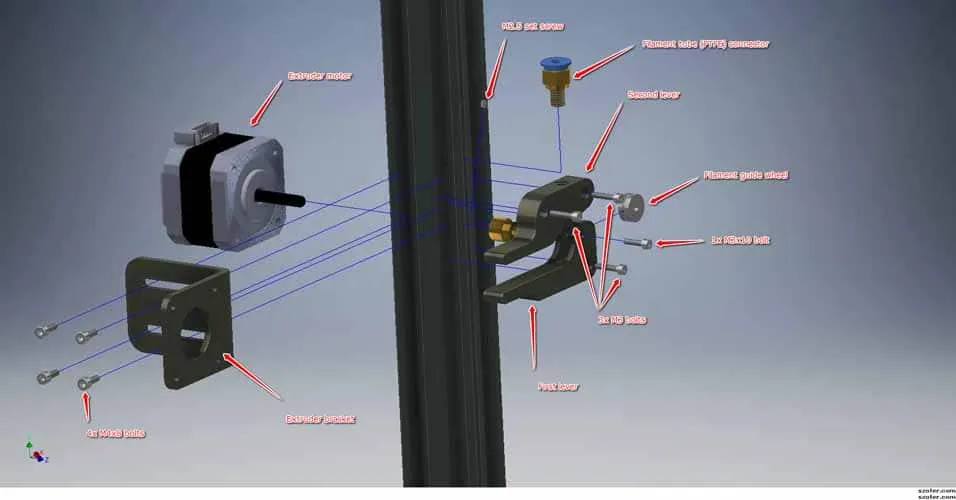

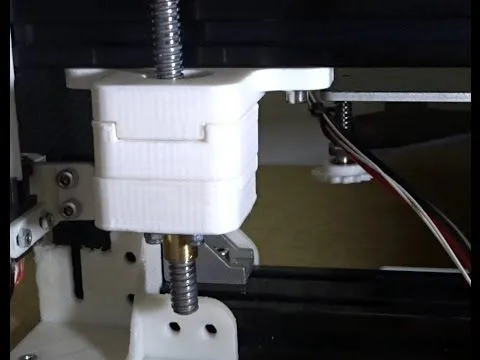

Essential Tools for Tevo Tarantula Z Offset

You’ll need a few essential tools. First, you’ll want a piece of paper. Ordinary printer paper works fine. This will be used to gauge the distance between the nozzle and the print bed. Next, a small tool is needed to adjust the Z offset. Finally, you will need your Tevo Tarantula printer itself and the ability to access its control panel or LCD screen, where you can adjust settings. Having a pair of tweezers can be helpful for removing any stray filament.

Safety Precautions Before Adjusting the Z Offset

Before you start adjusting the Z offset, always ensure your printer is unplugged or turned off for safety, especially if you’re working near the heated bed and nozzle. Be cautious when handling the hotend and nozzle. The nozzle can reach high temperatures during printing. Make sure the nozzle is cool before touching it to prevent burns. Double-check that your print bed is clean and free of any debris that could interfere with the calibration process. Wear safety glasses to protect your eyes from potential filament fragments.

Step-by-Step Tevo Tarantula Z Offset Calibration

Now, let’s get into the step-by-step process of setting up your Tevo Tarantula Z offset. This procedure involves careful adjustments and real-time observation. The best method is often trial and error, so don’t worry if it takes a few tries to get it right. Once you’ve done it a couple of times, the procedure will become second nature.

Preheating the Bed and Nozzle

Before starting, preheat your Tevo Tarantula’s bed and nozzle to the temperatures you’ll use for your print. This is essential because the thermal expansion of the nozzle and bed can affect the Z offset. This allows the printer to reach operating temperature which ensures more accurate measurements. Typically, PLA prints around 60°C for the bed and 200°C for the nozzle, but check the filament specifications for optimal temperatures.

Accessing the Z Offset Settings on Your Tevo Tarantula

On the Tevo Tarantula, you typically access the Z offset settings through the printer’s control panel or LCD screen. The exact location of these settings may vary slightly depending on your firmware version, but you’ll usually find them under the ‘Control’ or ‘Motion’ menu. Look for an option labeled ‘Z Offset’, ‘Z-height’, or something similar. Note down the current value before making any adjustments to have a reference point. Having a copy of your current Z-offset can prevent you from having to reset to the default setting.

Adjusting the Z Offset During Printing

The best way to calibrate the Z offset is while the printer is laying down the first layer. Start a print of a test model or a large, flat shape. As the first layer is printing, use the control panel to fine-tune the Z offset. If the nozzle is too far, reduce the Z offset value (making it more negative) in small increments (0.02mm to 0.05mm). If the nozzle is too close, increase the Z offset (making it less negative or more positive). Observe the first layer carefully, and adjust until you achieve the perfect squish. This method allows you to see the results of each adjustment immediately.

Fine-tuning the Z Offset for Optimal First Layer Adhesion

The goal is to achieve a slight flattening of the filament strands without causing the nozzle to scrape the bed. When the offset is perfect, the first layer will appear smooth and well-adhered. The filament should be slightly squished onto the bed, but you should still be able to see the individual strands. If the first layer looks transparent, the nozzle is too far. If you see ridges or the nozzle is scraping the bed, the nozzle is too close. Continue to make minor adjustments until the first layer is perfect. This will ensure a good print.

Tips for Achieving the Perfect First Layer

For achieving the perfect first layer, slow down the initial printing speed to about 15-20mm/s to allow for better adhesion and prevent the filament from being dragged across the bed. Ensure your print bed is level before calibrating the Z offset. A level bed is a prerequisite for accurate Z offset adjustments. Use a test print like a single-layer square or a calibration pattern to visually assess the first layer. Watch closely as the nozzle lays down the filament. The ideal first layer should show a slight squish, where the lines merge without gaps or ridges. Pay close attention to the four corners of the print to ensure the bed is level.

Troubleshooting Common Z Offset Problems

Even after calibrating the Z offset, you might encounter some issues. Here’s how to troubleshoot common problems and achieve the best results. Don’t get discouraged if you face these problems. They are all solvable with minor adjustments and a bit of patience.

Nozzle Too Far from the Bed

If the nozzle is too far from the bed, the filament won’t stick, and you will see gaps between the lines. This often results in a messy first layer, with filament curling up or detaching from the bed. Increase the Z offset (make it less negative or more positive) in small increments to bring the nozzle closer to the bed. Observe the first layer and adjust until the filament starts to adhere correctly.

Nozzle Too Close to the Bed

When the nozzle is too close, the filament will be excessively squished. The nozzle might scrape the bed, causing ridges or a rough surface. This can also lead to clogged nozzles. Decrease the Z offset (make it more negative) to lift the nozzle slightly. Check the first layer to ensure a smooth finish without any scraping sounds.

Uneven First Layer Adhesion

If some parts of the first layer adhere well, while others don’t, the bed might be unlevel. This issue can create an uneven first layer and print failures. Ensure that your bed is level by using the bed leveling screws or the auto-bed leveling system. You may need to re-level the bed and re-calibrate the Z offset after leveling. A consistently level bed will make it easier to achieve the proper Z offset setting.

Advanced Z Offset Techniques & Tips

Once you’ve mastered the basics, you can try some advanced techniques to get even better print results. Experimenting with these techniques can help you dial in your printer settings.

Using Bed Leveling to Assist Z Offset

Bed leveling and Z offset are closely related. Before setting the Z offset, ensure your bed is level. Once the bed is level, the Z offset can be adjusted precisely to fine-tune the distance between the nozzle and the bed. Many printers have auto-bed leveling systems, which can simplify this process. If you use auto-bed leveling, still double-check the Z offset to ensure perfect first-layer adhesion.

Saving and Storing Your Z Offset Settings

After calibrating the Z offset, save the settings on your printer. This ensures that the Z offset is retained, and the printer doesn’t revert to the default settings. On the Tevo Tarantula, there’s usually a ‘Save Settings’ option within the printer’s menu. Save these settings to the EEPROM or your printer’s memory. Make a note of your current setting, just in case you need to reset it later.

Maintaining Your Tevo Tarantula for Consistent Z Offset

Maintaining your Tevo Tarantula is crucial for consistent Z offset performance. Regular maintenance will ensure your printer stays in optimal condition, ensuring accurate and reliable Z offset settings. Make sure to regularly check your printer.

Cleaning the Print Bed Regularly

Clean your print bed before each print to remove any residue and ensure good adhesion. Use isopropyl alcohol and a clean cloth to wipe the bed. Avoid touching the bed with your bare hands, as the oils from your skin can affect adhesion. A clean print bed is a critical factor for consistent Z offset performance and a perfect first layer. Regularly cleaning the bed will solve a variety of adhesion problems.

Regularly Checking and Tightening Hardware

Check and tighten all the screws and belts on your Tevo Tarantula. Loose belts and screws can affect the printer’s movements and compromise the accuracy of the Z offset. Regularly inspect the printer’s frame, bed, and hotend assembly for any signs of wear or looseness. Proper maintenance of your Tevo Tarantula ensures the print quality.